Exploring How Open-Ended Innovation Drives the Lithography Roadmap with Erik Hosler

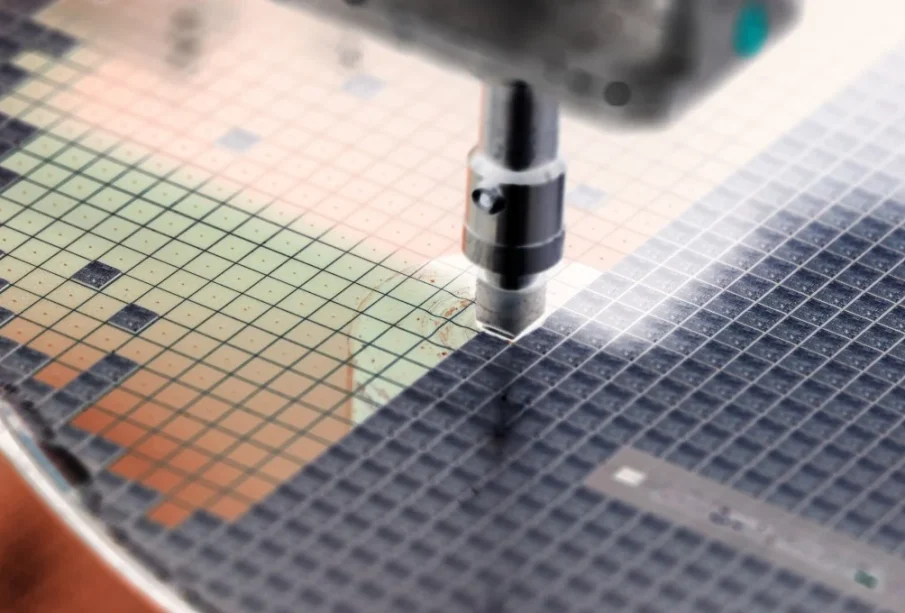

Semiconductor technology has long been defined by its precision, engineering marvels measured in atoms, and roadmaps plotted in nanometers. But behind this clarity lies a truth that defies linear planning: progress is unpredictable. Erik Hosler, a strategic thinker and veteran of EUV development, sees this uncertainty not as a liability but as a feature. In the world of advanced lithography, asking questions has become as important as answering them.

This philosophy came through clearly at the SPIE Advanced Lithography conference. Gone are the days when the roadmap was merely a ladder of smaller nodes and tighter pitches. Today’s sessions featured topics like quantum experimentation, resist stochastics, and AI-driven process modeling, all areas rich in ambiguity and open-ended potential. The takeaway? The future of lithography will not be a straight line. It will be a network of curiosity-fueled pivots.

A Roadmap Built on Questions

Lithography once offered a clear playbook. Reduce wavelength. Improve optics. Control alignment. The challenge was engineering, not exploration. But that’s no longer the case. As we approach physical and economic limits, the next big steps are not obvious. They must be discovered.

It has led to a subtle yet powerful shift: the roadmap is now driven by inquiry. Tools are being developed not only to solve problems but also to probe them. It includes high-resolution metrology systems that can detect unpredictable stochastic defects or novel resists designed to reveal how energy is absorbed and scattered at sub-nanometer scales.

The idea is to create experimental spaces inside the manufacturing flow, safe zones for trial and error. Rather than optimizing what we already know, engineers are building systems that ask what else is possible.

At the heart of this approach is a belief in open-ended innovation. Instead of betting everything on a single breakthrough, the industry is creating ecosystems where ideas can collide, mutate, and recombine. Erik Hosler notes, “Lots of great things are going on, and something will emerge.”

His statement captures the tone of SPIE and the broader shift in semiconductor thinking. The question is no longer what comes after EUV or 3 nm nodes, but what tools, processes, and ideas will appear when we stop assuming we know the answer.

Rethinking Metrics

With this shift comes a rethinking of success itself. Traditional KPIs like overlay, CDU, and defectivity still matter, but they no longer tell the whole story. How do you measure progress when the goal is exploration? The answer, increasingly, is diversity of thought, tools, and partners.

Metrics now include how many hypotheses are evaluated per cycle, or how many experimental parameters a resist platform can tolerate. Design of Experiments (DOE) is being reimagined as a strategy for structured uncertainty. And machine learning is being employed not just for pattern recognition, but for question generation.

This fluid approach allows researchers to chase intuition without losing accountability. By tracking exploration as rigorously as execution, the industry can learn faster, even when it fails.

The Role of Conferences and Collaboration

Events like SPIE play a unique role in enabling this open-endedness. While many industry gatherings focus on product roadmaps or market trends, SPIE remains a forum for unsolved problems. It is here that unproven ideas get their first audience, and where impossible concepts often get a second look.

The format itself encourages risk-taking. Poster sessions, cross-track symposia, and informal evening panels create spaces where divergent thinking thrives. Collaboration becomes not just encouraged but inevitable.

In this context, even unlikely connections between metrology and AI ethics or between resist chemistry and quantum tunneling are not outliers. They are signals that the roadmap is growing in dimensions we hadn’t charted before.

Education in an Era of Ambiguity

This new mode of innovation demands new educational models. Engineers can no longer specialize in only one branch of science. Instead, they must become literate across domains. That means training in optics and data science. Exposure to chemistry and systems thinking. Comfort with both cleanroom tools and cloud-based simulation. Increasingly, it means embracing ambiguity as a professional skill.

Leading companies are building internal fellowships and sandbox programs that allow technical staff to step away from their day jobs and explore “what if” ideas. Academic programs introduce classes in creative engineering and hypothesis framing. If yesterday’s lithography experts were tool specialists, tomorrow’s would be possibility specialists.

Risk, Failure, and Serendipity

One of the hardest truths in open-ended innovation is accepting failure as a feature, not a bug. Some ideas won’t work. Others will work, but not as expected. Serendipity, once a soft science term, is becoming an operational goal.

It doesn’t mean quality or yield are being neglected. Rather, it means the industry is building controlled zones of failure, buffered from production timelines but rich in insight. These spaces help uncover not just what can be done, but what should be done.

Such an approach mirrors the scientific method more than the traditional supply chain. It rewards curiosity and thrives on iteration. When something does emerge, it tends to be stronger for having survived the gauntlet of doubt.

A Living Roadmap

In the past, the roadmap was a destination. Today, it is a process, one that adapts, reshapes, and responds to what the community discovers along the way. This approach is slower in some respects but more robust in others. It reflects the realities of a field that is no longer only about scaling, but also about understanding.

This living roadmap is not just more resilient, but more inviting. It welcomes new voices, new frameworks, and unexpected contributions without demanding immediate ROI. That patience may be its greatest strength.

Embracing the Unexpected

The future of lithography will not be delivered on schedule. It will arrive through exploration, collaboration, and occasional chaos. But that’s the point. If we knew exactly where we were going, we wouldn’t need a roadmap at all.

By welcoming ambiguity and investing in creativity, the semiconductor industry is positioning itself to meet whatever challenges arise. It may not look like the roadmaps of the past, but it might just be better prepared for the future.